Pendulum Friction Tester also called building tester, Construction Tester, friction coefficient meter , Pendulum Friction Tester ,

highway pavement tester, Anti-skid performance tester.

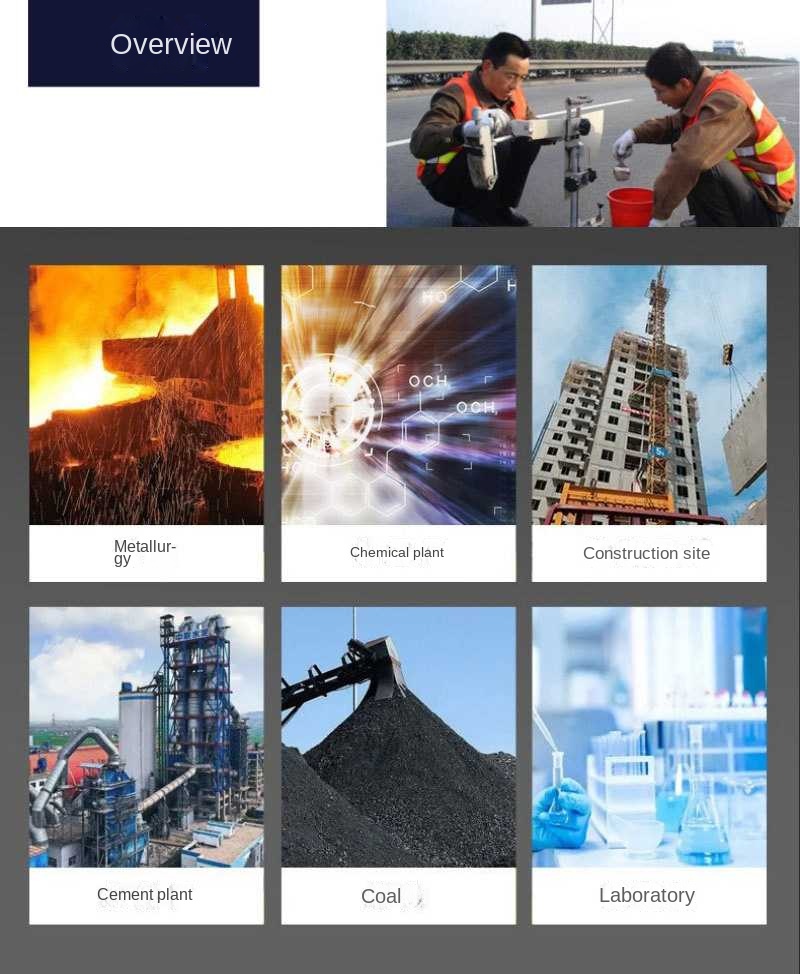

Pendulum friction tester overview:

The pendulum friction tester is a friction coefficient tester. It is mainly used for testing the skid resistance of high-grade highways, urban roads and airport runways. The pendulum friction tester is suitable for measuring the friction coefficient of road surfaces, and can be adjusted up and down. The pendulum friction tester is easy to debug, easy to operate, accurate test data, greatly improved stability, and can be used indoors and outdoors. It is one of the indispensable testing instruments in the construction of special equipment such as high-grade highways.

Operation rules of pendulum friction tester

1) Point selection, on the test road section, along the left wheel track in the driving direction, select five representative measuring points, each measuring point is 5~10m apart.

2) Leveling of the pendulum friction tester: place the pendulum friction tester on the measuring point, and make the swing direction consistent with the driving direction, and turn the leveling screw to center the level bubble.

3) Zero adjustment: loosen the fixed male handle, turn the lifting handle to raise the pendulum and swing freely, and then tighten the handle. Move the pendulum to the right, press the release switch so that the snap ring enters the slot of the release switch and is at the horizontal release position, then release the release switch, at this time the pointer should be moved to close to the dial. Press the release switch to move the pendulum to the left and drive the pointer to move upward. When the pendulum reaches the highest position and falls, catch the pendulum with your left hand. At this time, the pointer should point to zero. If it does not point to zero, you can tighten or loosen it slightly. Repeat this operation for the felt ring adjusting nut until the pointer points to zero.

4) Calibrate the sliding length: Use a rubber brush to remove loose particles and debris on the road surface within the swing range. Let the pendulum hang freely, set the standard ruler 126mm in the parallel swing direction outside the rubber sheet, loosen the fastening handle and then turn the lifting handle to lower the pendulum slowly, when the rubber sheet on the slippery block just touches the road surface, lift the lifting handle to make the slippery block Lift up, move the pendulum to the right and turn the lifting handle to lower the pendulum for a certain distance, then lower the lifting handle to move the pendulum slowly to the left until the edge of the rubber sheet just touches the end of the 126mm ruler facing the road, and then manually Lift the lifting handle to lift the sliding block upwards, and make the pendulum continue to move to the left, put down the lifting handle and slowly move the pendulum to the right so that the edge of the rubber sheet touches the road again. The distance between the two contact points of the rubber sheet and the road surface is 126mm. If it does not conform to 126mm, you can turn the lifting handle, and then repeat the above steps for rough adjustment. When it basically conforms to 126mm, tighten the fixed handle.

5) Measurement of pendulum friction tester: Sprinkle the road surface with water, and scrape it with a rubber brush to wash off the mud, then sprinkle water, and press the release switch to slide the pendulum on the road surface, and the pointer can indicate the friction of the road surface Coefficient (generally do not record for the first time), when the pendulum moves to the right, catch the pendulum rod with the left hand, lift the lift handle with the right hand, and move the pendulum to the right, press the switch to make the pendulum ring enter the release switch, and Pull the swing needle until it is close to the needle puller, repeat the stop item, measure it for five times, record the value each time, the difference between the five values is not more than three units, (that is, one and a half grids of the dial), if the difference is greater than three unit, check the reason and repeat the above operations again until the regulations are met.

6) Pendulum friction tester measurement results: each measuring point represents the friction coefficient value of the measuring point with the average value of five measurement readings, and divides the average value of the friction coefficient of the five measuring points by 100, which is the friction of the road surface coefficient.

Dongguan Runzhi Electronics Co., Ltd.-Testing Instrument Division is mainly engaged in various laboratory supplies and testing instruments and equipment: workbench, environmental experiment instrument, element detection combined instrument, floor special residual sag tester, lock size tester , Straight-line right angle detector, microcomputer push-pull force meter, static bending strength tester, high-precision video projector, caster tester, falling ball tester, falling sand meter, 90-degree peel strength tester, scratch resistance tester, Grinding tester, gloss meter, whiteness meter, energy meter, specific gravity meter, infrared thermometer, viscometer, thickness meter, depth meter, analytical balance, calipers, feeler gauge and other instruments and equipment are available. Welcome new and old customers from all over the country to call and post for consultation:

Website: https://www.instrumentvip.com/

Tel: 86+13712847488

Contact person: Mr. Zheng