Salt Spray Chamber Introduction

Salt spray chamber also known as Salt spray tester Salt fog tester corrosion test chamber Salt spray corrosion test chamber Salt spray corrosion test box corrosion resistance test machine corrosion resistance performance testing machine

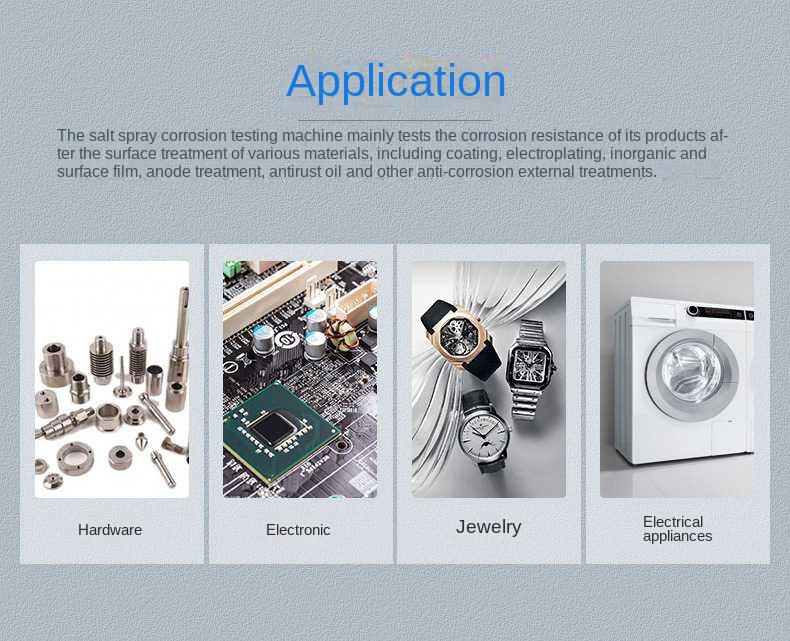

The salt spray test chamber can evaluate the ability of salt spray corrosion of materials and their protective layers, and the process quality comparison of similar protective layers. At the same time, it can evaluate the ability of certain products to resist salt spray corrosion; the salt spray test chamber is suitable for parts, Salt spray corrosion test of electronic components, protective layer of metal materials and industrial products.

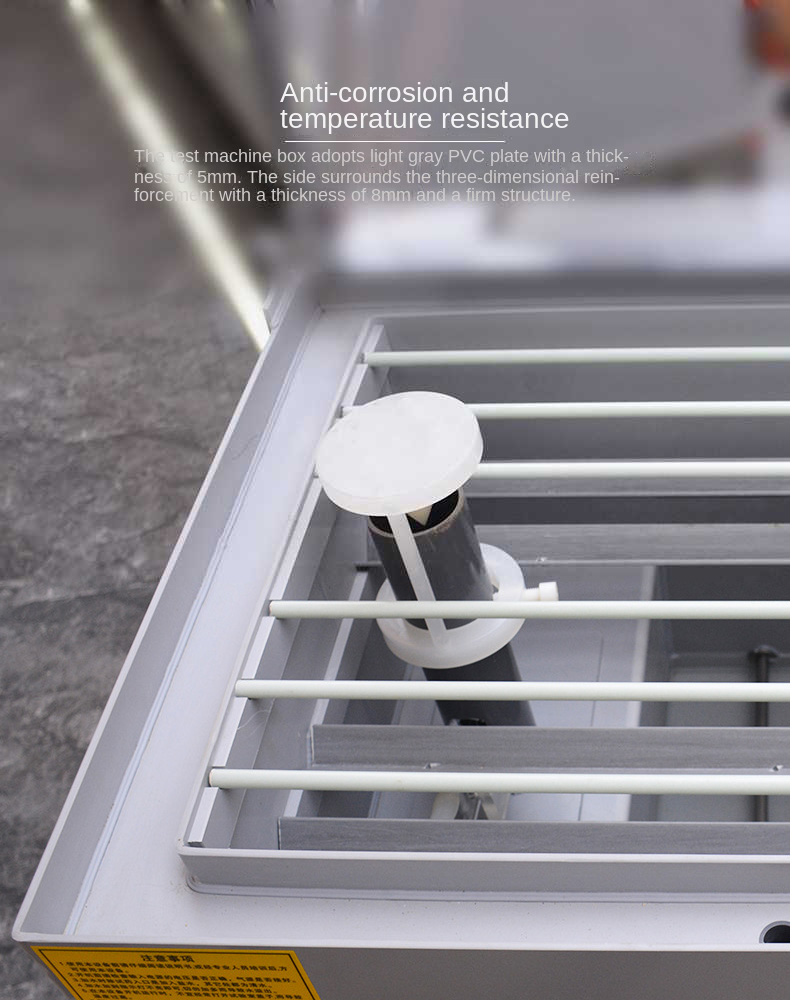

Salt spray test chamber equipment material:

The material of the salt spray test chamber is generally PVC and PP.

When doing neutral salt spray test (NSS test) and salt spray test (SS test), PVC reinforced rigid plastic board is used.

PP board is used for acetic acid salt spray test (ASS test) and copper accelerated vinegar instinct test (CASS test).

Compared with PVC board, PP board is more resistant to high temperature and strong corrosion.

Salt spray test chamber principle:

Salt spray test chamber principle:

There are four kinds of tests that can be done in the salt spray test chamber: neutral salt spray test (NSS), copper accelerated acetic acid salt spray test (CASS), alternating salt spray test, and acetic acid salt spray test (ASS test). Of course, different tests not only require different solutions, but also the design and structure of the box may also be different.

1. The temperature of the neutral salt spray test (NSS) test chamber is required to be (35±2)°C, the humidity is greater than 95%, and the fog reduction is 1~2mL/80cm*h. The nozzle pressure is 78.5~137.3kPa (0.8~1.4 kgf/cm2). In the salt spray test chamber, the salt water containing (5 ± 0.5)% sodium chloride and the pH value of 6.5~7.2 is sprayed through the spray device, so that the salt spray settles on the test piece to be tested, and after a certain period of time, it is observed. Corrosion state of the surface.

2. Copper-accelerated acetic acid salt spray test (CASS) is based on the general salt spray test, adding copper chloride 2 hydrate to 5% sodium chloride brine to make the concentration 0.26g/L, and then adjusting the pH with acetic acid. Make the pH value of the salt spray collection solution 3.1-3.3. (Test reference GB/T 10125 Artificial atmosphere corrosion test)

3. Alternating salt spray test is a comprehensive salt spray test (realized by alternating salt spray test chamber.

Dongguan Runzhi Electronics Co., Ltd.-Testing Instrument Division is mainly engaged in various laboratory supplies and testing instruments and equipment: workbench, environmental experiment instrument, element detection combined instrument, floor special residual sag tester, lock size tester , Straight-line right angle detector, microcomputer push-pull force meter, static bending strength tester, high-precision video projector, caster tester, falling ball tester, falling sand meter, 90-degree peel strength tester, scratch resistance tester, Grinding tester, gloss meter, whiteness meter, energy meter, specific gravity meter, infrared thermometer, viscometer, thickness meter, depth meter, analytical balance, calipers, feeler gauge and other instruments and equipment are available. Welcome new and old customers from all over the country to call and post for consultation:

Website: https://www.instrumentvip.com/

Tel: 86+13712847488

Contact person: Mr. Zheng