Products

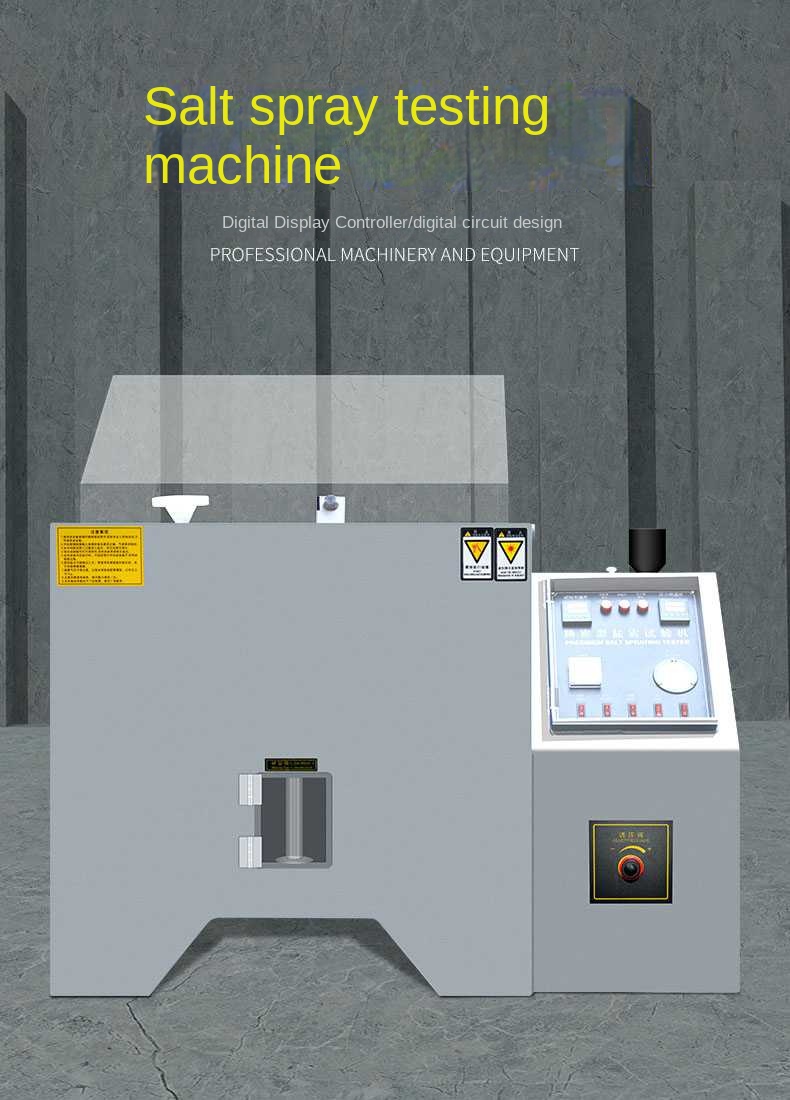

salt spray chamber

Five Advantages Of Products

- The salt spray chamber is an environmental test that mainly uses artificially simulated salt spray environmental conditions created by salt spray test equipment to assess the corrosion resistance of products or metal materials.

- The salt spray chamber is suitable for salt spray corrosion tests of components, electronic components, protective layers of metal materials and industrial products.

- The salt spray chamber is integrally molded and welded at high temperature, which is corrosion-resistant, easy to clean, and has no leakage.

- Both indoor and outdoor tanks of salt spray are integrally molded with epoxy glass fiber reinforced plastic, which has the characteristics of light weight, corrosion resistance, high strength, no leakage, smooth surface, smooth and easy to clean.

- Salt spray chamber The top cover of the salt spray chamber is designed with a top angle of 110~112°C to prevent the condensed water in the chamber from dripping directly on the sample. The water-sealed form prevents the salt mist from overflowing, and the jacketed air duct is heated to make the working room heat up quickly and the temperature distribution is even.

Product Details

Salt Spray Chamber Introduction

Salt spray chamber also known as Salt spray tester Salt fog tester corrosion test chamber Salt spray corrosion test chamber Salt spray corrosion test box corrosion resistance test machine corrosion resistance performance testing machine

The salt spray chamber is an environmental test that mainly uses artificially simulated salt spray environmental conditions created by salt spray test equipment to assess the corrosion resistance of products or metal materials.

(1) The neutral salt spray test is the earliest and most widely used accelerated corrosion test method. It uses 5% sodium chloride saline solution, and the pH value of the solution is adjusted in the neutral range (6~7) as a solution for spraying. The test temperature is 35°C, and the sedimentation rate of salt mist is required to be between 1~2ml/80cm2.h.

(2) The acetic acid salt spray test is to add some glacial acetic acid to 5% sodium chloride solution.

(3) Copper salt accelerated acetic acid salt spray test is a rapid salt spray corrosion test recently developed abroad. The test temperature is 50°C, and a small amount of copper salt-copper chloride is added to the salt solution to strongly induce corrosion. Its corrosion rate is about 8 times that of the NSS test.

(4) The alternating salt spray test is a comprehensive salt spray test.

Salt spray chamber test method

GB/T2423.17-2008 salt spray test method

GB/T 2423.18-2000 "Basic Test Rules for Electrical and Electronic Products Ka"

GB/T10125-1997 Artificial atmosphere corrosion test_salt spray test

Technical conditions of GB/T10587-2006 salt spray test chamber

GB10593.2-1990 Measurement method of environmental parameters of electric and electronic products

GB/T1765-1979 Determination of heat and humidity resistance, salt spray resistance, weather resistance (artificial acceleration) paint film system test

GB/T1771-2007 Determination of neutral salt spray resistance of paints and varnishes

GB/T12967.3-2008 Aluminum and aluminum alloy anodic oxide film detection method - Part 3: Copper acceleration

GB/T5170.8-2008 and equivalent IEC, MIL, DIN, ASTM and other related standards

Salt spray chamber test method

Available test methods:

Neutral salt spray test (NSS test) Salt spray test (SS test)

Acetic salt spray test (ASS test)

Copper Accelerated Vinegar Instinct Test

High temperature and humidity test

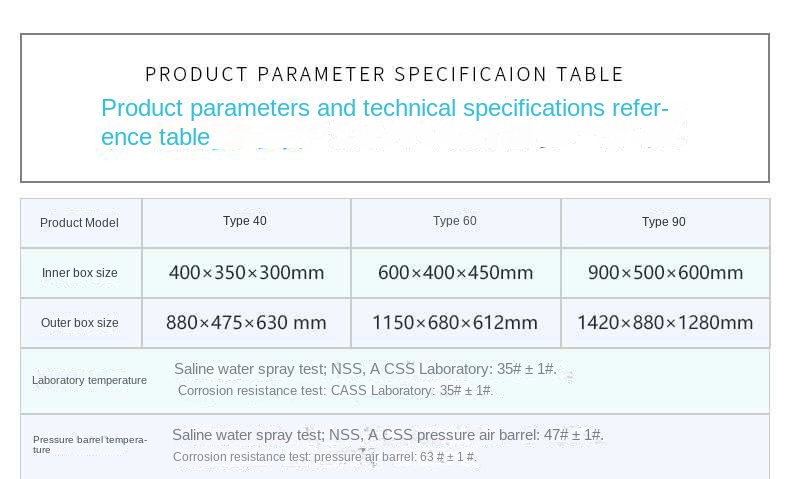

Test temperature: neutral salt spray test: laboratory: 35℃±1℃, b. saturated air barrel: 47℃±1℃, acid corrosion test: laboratory: 50℃±1℃, b. saturated air barrel: 63 ℃±1℃, can also be set according to JIS, CNS and other standards

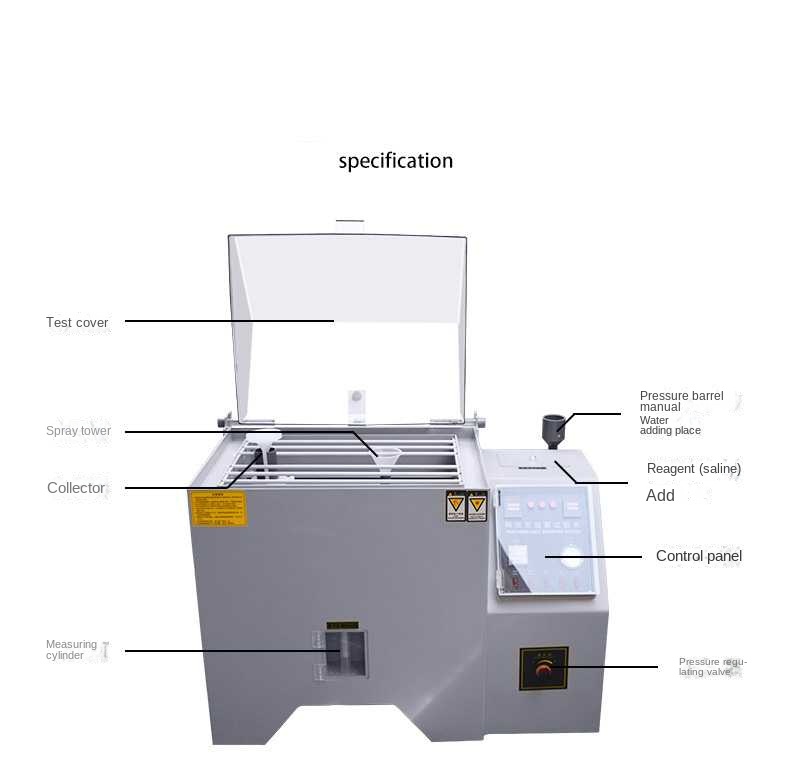

Salt spray chamber box structure

The salt spray chamber is integrally molded and welded at high temperature, which is corrosion-resistant, easy to clean, and has no leakage.

Salt spray chamber tower-type spray system, and equipped with salt liquid filtration system, no crystallization nozzle, salt spray distribution is uniform, and the settlement amount can be adjusted freely.

The cover of the salt spray chamber is made of transparent material, so that the test items and spray conditions in the box can be clearly seen.

The salt spray chamber adopts a water-tight structure between the cover and the box body, and there is no salt spray overflow.

The circuit control panel and other vital parts of the salt spray chamber are fixed in positions that are convenient for inspection and maintenance. The side cover door with door lock opening is not only beautiful, but also convenient for maintenance.

Add some glacial acetic acid to the sodium solution.

Salt spray chamber operation method

1. Install the internal parts of the salt spray chamber: tower spray device, funnel, round rod, V-shaped sample holder, etc.

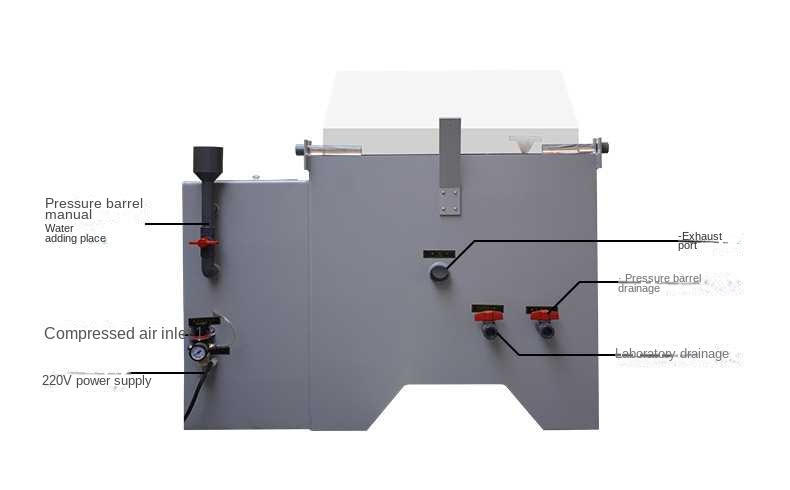

2. Connect the air source, after the power is connected, turn on the power switch.

3. Add water to the pressure barrel and the box, stop adding water after the two low water level lights go out, and add water to the sealing groove to seal.

4. Mix pure water and sodium chloride salt at a ratio of 1:20. Pour the prepared solution into the entrance of the reagent (just turn off the low salt water light).

5. After all the lights are off, we can turn on the operation, spray, and timing switches, and the defogging switch can only be turned on after the test is over.

6. According to the test requirements, the equipment has two spraying methods, continuous and periodic (when continuous spraying, T1 and T2 tables are all set to 0, and when intermittent spraying, T1 is set as working time, and T2 is resting time).

Reminder: Due to the continuous upgrading of the salt spray chamber, the picture of the salt spray chamber is for reference only, please email us for details! More high-quality products welcome your consultation!

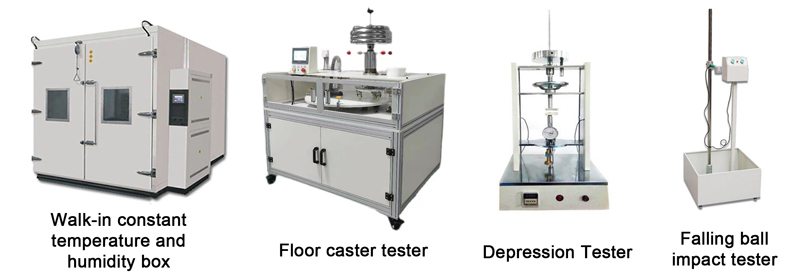

Dongguan Runzhi Electronics Co., Ltd.-Testing Instrument Division is mainly engaged in various laboratory supplies and testing instruments and equipment: workbench, environmental experiment instrument, element detection combined instrument, floor special residual sag tester, lock size tester , Straight-line right angle detector, microcomputer push-pull force meter, static bending strength tester, high-precision video projector, caster tester, falling ball tester, falling sand meter, 90-degree peel strength tester, scratch resistance tester, Grinding tester, gloss meter, whiteness meter, energy meter, specific gravity meter, infrared thermometer, viscometer, thickness meter, depth meter, analytical balance, calipers, feeler gauge and other instruments and equipment are available. Welcome new and old customers from all over the country to call and post for consultation:

Contact person: Mr. Zheng

Dongguan Runzhi Electronics Co., Ltd.

Contact Person: Mr. Zheng

Department: Business Department

Post: Sales Manager

Telephone: +86 13712847488

Landline: +86 13717173764

Company Address: Room 101, 33 Zhenma Road, Dalingshan Town, Dongguan City, Guangdong Province,China

Factory Address: Room 101, No. 33 Zhenma Road, Dalingshan Town, Dongguan City, Guangdong Province,China

Website: runzhi.us764.com

Previous: electronic moisture tester (elect...

Next: incubator