Products

friction coefficient meter

Five Advantages Of Products

- Pendulum friction coefficient tester is mainly used for high-grade highway and laboratory, airport runway road friction coefficient (but also can be used for rubber runway, floor tile skid resistance detection), in order to assess the skid performance of the road surface, pendulum friction coefficient tester is also used for stone accelerated grinding machine stone standard specimen polishing value measurement, stone accelerated grinding machine must be used with the instrument.

- Pendulum friction coefficient tester is a friction coefficient tester. The average of five readings at each measuring point represents the pendulum value of the measuring point, and the average of the pendulum values at the five measuring points represents the pendulum value of the measured section.

- Pendulum friction coefficient tester is a dynamic pendulum impact instrument. It is developed according to the basic principle that

- Pendulum friction coefficient tester is a precision instrument, easy to operate, intuitive reading, measurement reading, immediate dial pointer reading (referred to as

- Pendulum friction coefficient tester good product quality, reasonable price, after-sales guarantee.

Product Details

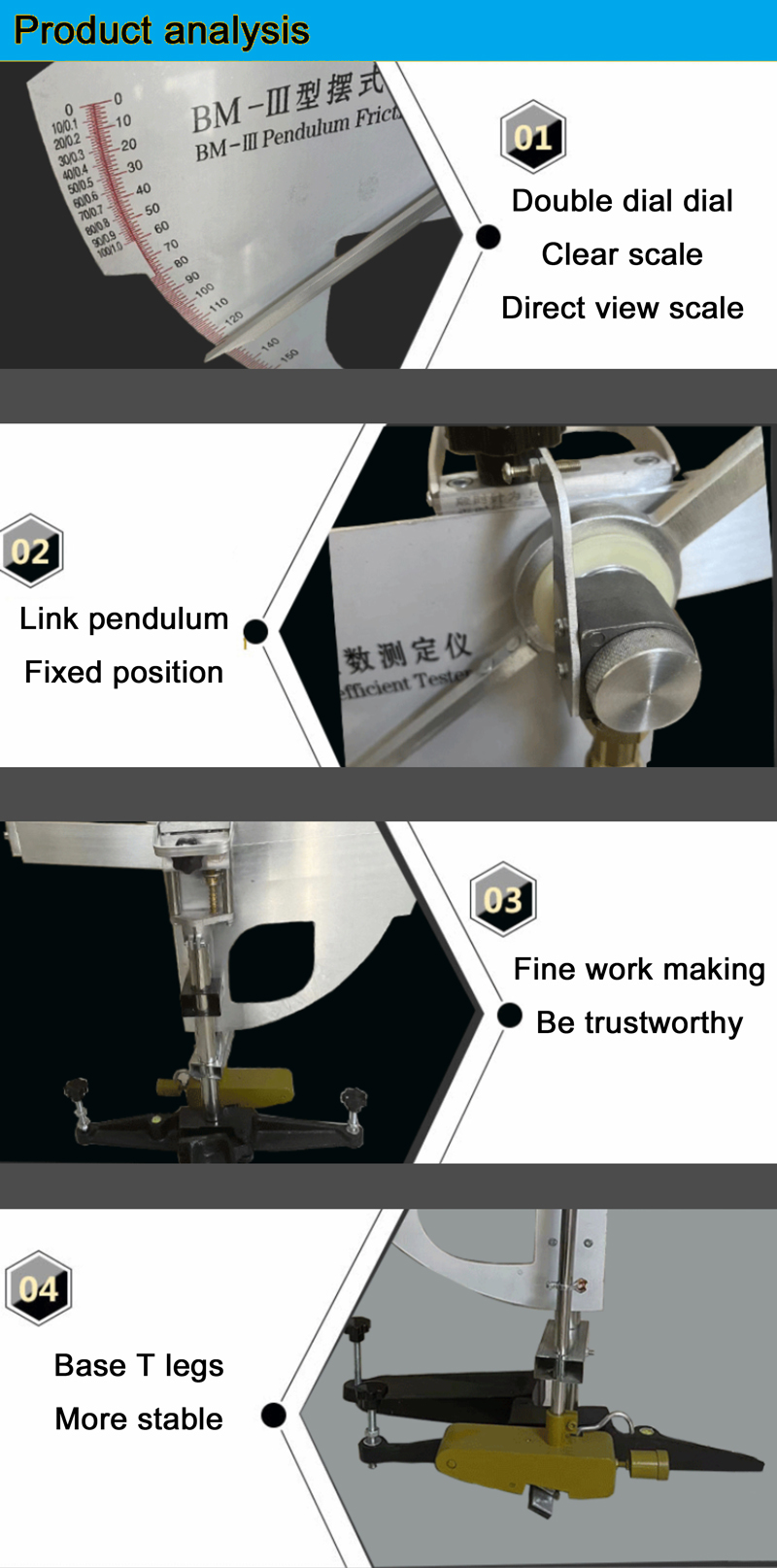

Introduction of BM-III Pendulum Friction Coefficient tester

With the development of transportation, the anti-skid problem of highway, urban road and airport runway has aroused the general attention of related departments. Pendulum friction coefficient tester (hereinafter referred to as pendulum tester) is an instrument for measuring the friction coefficient of road surface, airport runway, marking paint and so on. It is also possible to measure the typical road friction coefficient as one of the bases for determining the formula of seed preservation tire. The instrument is convenient to debug, simple to operate, testing on the traffic impact is small, the data is stable,It can be used both indoors and outdoors.

Principle of BM-III pendulum friction coefficient tester:

Pendulum instrument is a dynamic pendulum impact instrument. It is developed according to the basic principle that "the potential energy loss of the pendulum is equal to the work done by overcoming the friction of the road surface when the rubber sheet installed at the end of the pendulum arm slides over the road".

Parameters of BM-III pendulum friction coefficient tester:

1, swing moment: 615000g*mm

2. The weight of the pendulum: 1500 RMB 30g

3. Pendulum moment of gravity: 410 × 5mm

4. Positive static pressure of rubber sheet on road surface: 2263g

5, swing head tilt 5° free down to swing stop times, not less than 70 times.

6. The outer edge of the rubber sheet is 508mm away from the swing center.

7. The total weight of the instrument is about 15Kg.

BM-III pendulum friction coefficient tester:

1. Selection Points:

(1) On the test section, five representative measuring points are selected along the left wheel track in the driving direction, and each measuring point is about 5-10 meters apart.

2, instrument leveling:

(A) Place the instrument on the measuring point (see appendix for calibration method) and make the direction of swing consistent with the driving direction; (B) Turn the leveling screw; (J) leveling the bubble; (M) is centered.

3. Zero adjustment:

(1) Relax the fixed handle (A and B), turn the lifting handle (C) to raise the pendulum and swing freely, and then tighten the handle (A and B);

(2) Rotate to the right and press the release switch (D); Make the clapper (N) into the release switch slot and in the horizontal release position, then release the release switch (D), and the pointer (H) should be moved close to the dial pin;

(3) Press the release switch (D) Swing to the left. When the pendulum falls after reaching a high position, catch the pendulum rod with your left hand. At this time, the pointer should point to zero. If it does not point to zero, you can tighten or loosen the felt country adjusting nut (E) slightly.

4. Calibration sliding length:

(1) Use a rubber brush to remove loose particles and debris on the road surface of the swinging fan

(2) Let the pendulum hang freely, set the standard ruler 126mm on the outside parallel swing direction of the rubber sheet (T), loosen the tightening handle (A and B), rotate the lifting handle (C), make the pendulum slowly down, when the slide block on the machine film (J) just contact the road, lift the lifting handle (P) to make the slide block (S) rise, will swing to the right movement, The shaft rotates the lifting handle (C) to make the pendulum drop for a certain distance, and then puts down the lifting handle to make the pendulum move slowly to the left until the edge of the rubber sheet just touches the road, and then lifts the lifting handle (P) with the hand to make the slipper (S) lift upward, and makes the pendulum continue to move to the left, and puts down the lifting handle (P). Move the pendulum slowly to the right so that the edge of the rubber touches the road again. The distance between two contact points on the same road surface of the rubber sheet should be 126mm(sliding length). If it does not conform to 126mm, you can turn the lifting handle (C) and repeat the above steps for rough adjustment. When it basically meets 126mm, firmly fix the handle (A and B) and correct it again. If the sliding length does not meet the standard, raise or lower the leveling screw (small) on the front of the instrument base to correct it, but the leveling bubble must be adjusted to make the sliding length meet the requirements. Then, put the pendulum in the horizontal release position.

5. Determination:

Pour water on the road, and scrape with a rubber brush to wash the mud, and then the wine, and press the release switch (D), so that the road slide, the pointer can indicate the friction coefficient value of the outlet (usually not recorded). When swinging back to swing, catch the swing rod with the left hand, lift the lifting handle with the right hand to raise the slide block, and swing to the right movement, press the switch, make the swing clamp ring into the release switch, and swing needle to tighten the needle, repeat this, measure five times (each time should drink), record the value of each time, If the difference is greater than three units, the reasons should be checked and the above operations should be repeated again until the requirements are met.

6. Determination results:

(1) The average value of five measured readings for each measuring point represents the friction coefficient value of the measuring point, and the average value of the friction coefficient of five measuring points;

(2) Take the readings. That is, the speed of the pointer on the dial (" swing value "for short) divided by 100 is the grinding control coefficient of the road surface, such as: swing value 33. The friction coefficient is 0.33.

Warm tip: Due to the pendulum friction coefficient tester upgrade, pendulum friction coefficient tester picture for reference only, details email consultation! More quality products welcome your consultation!

Warm tip: Due to the pendulum friction coefficient tester upgrade, pendulum friction coefficient tester picture for reference only, details email consultation! More quality products welcome your consultation!

Dongguan Runzhi Electronics Co., Ltd.

Contact Person: Mr. Zheng

Department: Business Department

Post: Sales Manager

Telephone: +86 13712847488

Landline: +86 13717173764

Company Address: Room 101, 33 Zhenma Road, Dalingshan Town, Dongguan City, Guangdong Province,China

Factory Address: Room 101, No. 33 Zhenma Road, Dalingshan Town, Dongguan City, Guangdong Province,China

Website: runzhi.us764.com

Previous: falling sand wear testing machine