Brief introduction of pneumatic diaphragm pump:

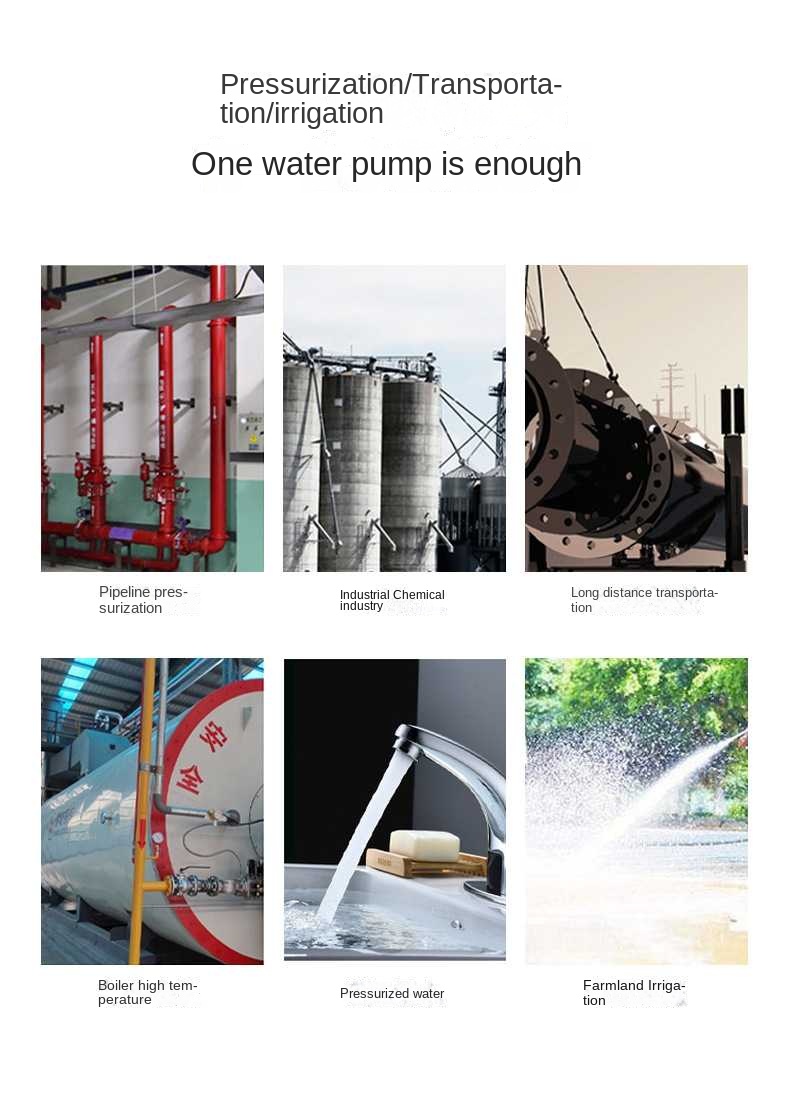

Pneumatic diaphragm pump is a new type of conveying machinery. It uses compressed air as the power source. It can pump all kinds of corrosive liquids, liquids with particles, high viscosity, volatile, flammable, and highly toxic liquids. . Pneumatic diaphragm pumps are mainly used in spray painting and ceramic industries, and in some other industries, they can also be used in environmental protection, wastewater treatment, construction, sewage discharge, and fine chemicals.

Working principle of pneumatic diaphragm pump:

Pneumatic diaphragm pump is a positive displacement pump driven by compressed air, whose volume changes due to the reciprocating deformation of the diaphragm. Its working principle is similar to that of a plunger pump. Due to the characteristics of the working principle of the pneumatic diaphragm pump, the pneumatic diaphragm pump has the following characteristics:

(1) The pump will not overheat: compressed air is used as power, and it is a process of expanding and absorbing heat when exhausting. When the pneumatic pump is working, the temperature is lowered, and no harmful gas is discharged.

(2) There will be no electric sparks: the pneumatic diaphragm pump does not use electricity as power, and it prevents static sparks after being grounded.

(3) It can pass liquid containing particles: because of the volumetric work and the inlet is a ball valve, it is not easy to be blocked.

(4) The shear force on the material is extremely low: how to suck in and how to spit out when working, so the agitation of the material is the least, and it is suitable for the transportation of unstable materials.

(5) The flow rate can be adjusted, and a throttle valve can be installed at the material outlet to adjust the flow rate.

(6) It has the function of self-priming.

(7) It can run dry without danger.

(8) It can work in diving.

(9) The fluid that can be transported is extremely wide, from low viscosity to high viscosity, from corrosive to viscous.

(10) There is no complicated control system, no cables, fuses, etc.

(11) Small size, light weight, easy to move.

(12) It is easy to maintain without lubrication, and will not pollute the working environment due to dripping.

(13) The pump can always maintain high efficiency and will not be reduced due to wear and tear.

(14) 100% energy utilization, when the outlet is closed, the pump stops automatically, and there is no equipment movement, wear, overload, or heat generation.

(15) There is no dynamic seal, easy maintenance to avoid leakage, and no dead point during work.

Advantages of using pneumatic diaphragm pump:

Pneumatic one-way diaphragm pump has six advantages of reliable quality, long service life, low noise, small vibration, never crash, and fine workmanship. It can not only pump flowing liquid, but also transport some difficult-to-flow media. It has self-priming pump, Many advantages of conveying machinery such as submersible pumps, canned pumps, mud pumps and trash pumps.

1. The flow is spacious and the passing performance is good. The maximum particle diameter allowed to pass is 10 mm. When pumping mud and impurities, there is little wear on the pump;

2. The pneumatic one-way diaphragm pump does not need irrigation and diversion, the suction lift is up to 8.8 meters, the lift is up to 84 meters, and the outlet pressure is ≧8.4bar;

3. The pneumatic one-way diaphragm pump has no rotating parts and no shaft seal. The pumped medium such as the diaphragm is completely separated from the moving parts of the pump and the workpiece medium, and the transported medium will not leak out. Therefore, when pumping toxic, volatile or corrosive media, it will not cause environmental pollution and endanger personal safety;

4. The head and flow can be adjusted steplessly through the opening of the air valve (air pressure adjustment between 1-8.4bar);

5. It can work submerged in the medium;

6. No need to use electricity, it is safe and reliable to use in flammable and explosive places;

7. Pneumatic diaphragm pump has simple structure, less wearing parts, simple structure, convenient installation and maintenance, and the medium conveyed by the pump will not touch the moving parts such as air distribution valve and connecting rod. Unlike other types of pumps, the rotor, piston, The wear of gears, blades and other components gradually reduces the performance;

8. It is easy to use and reliable in operation. It only needs to simply open and close the gas valve to start and stop. Even if the pump runs without medium for a long time or stops suddenly due to accidents, the pump will not be damaged. Once overloaded, the pump will stop automatically. , with self-protection performance, when the load returns to normal, it can start running automatically;

9. The pneumatic diaphragm pump does not need to be lubricated with oil, even if it is idling, it has no effect on the pump, which is a major feature of the pump;

10. It can transport viscous liquid (viscosity below 25000 centipoise).

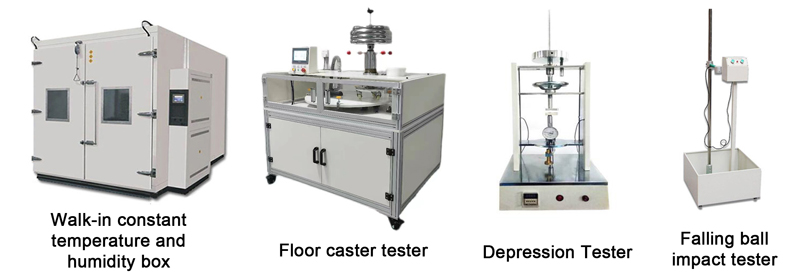

Dongguan Runzhi Electronics Co., Ltd. mainly engaged in special instruments and equipment are: Laboratory environment test instrument, element detection instrument, floor residual pitting meter, lock size tester, straight Angle detector, microcomputer push tension meter, static bending strength testing machine, high-precision image projector, caster testing machine, falling ball tester, falling sand meter, 90 degree peeling strength testing machine, scratch resistance tester, wear resistance tester, gloss meter, whiteness meter, Energy meter, hydrometer, infrared thermometer, viscometer, thickness meter, depth meter, analytical balance, caliper, gauge and other instruments and equipment. Website: https://www.instrumentvip.com/

Tel: 86+13712847488

Contact person: Mr. Zheng