Products

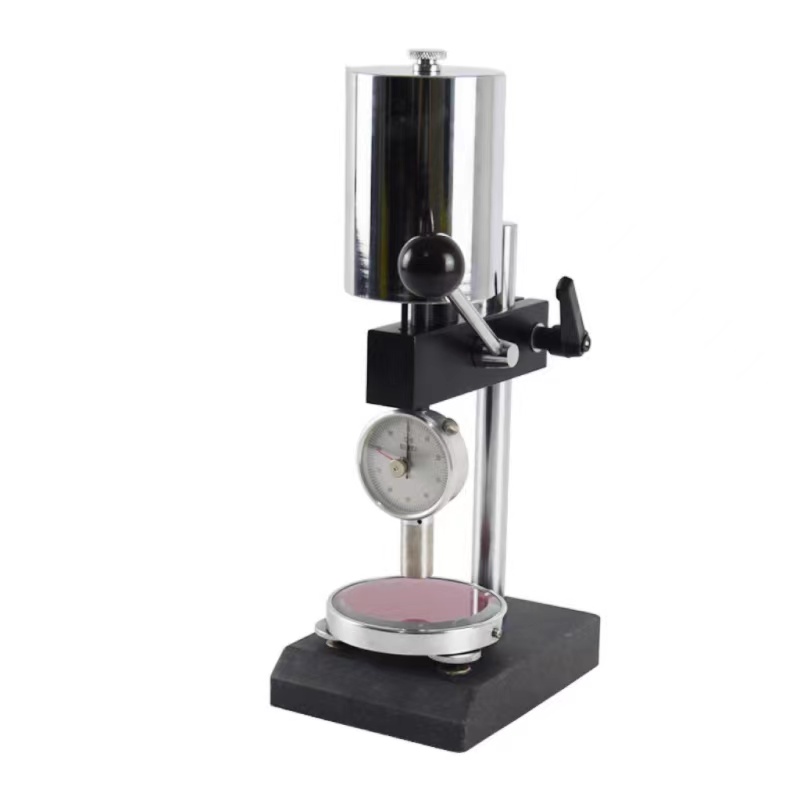

hardness tester

Five Advantages Of Products

- Hardness tester is a hardness testing instrument, used to test the hardness of products. Generally, the higher the hardness, the better the wear resistance.

- According to the principle, the durometer can be divided into: Richter hardness tester, Rockwell hardness tester, Brinell hardness tester, Shore hardness tester, Shore hardness tester, Papinell hardness tester, microhardness tester, Mohs hardness tester, Vickers hardness tester, etc.

- Hardness tester according to the measurement object is divided into: steel and cast steel, alloy tool steel, stainless steel, gray cast iron, ductile cast iron, cast aluminum alloy, copper zinc alloy (brass), copper tin alloy (bronze), pure copper, forged steel, heat treatment, carbonization, hardening layer, surface coating, steel, Non-ferrous metal and small and thin parts, rubber, plastic, IC sheet, jewelry and other fruit hardness tester, cement hardness tester, etc.

- Shore hardness tester is used to measure the hardness of rubber, foam, plastic and other materials, mainly HA and HD two kinds of hardness parameters, the former is soft rubber, the latter is hard rubber or plastic hardness parameters.

- Shore Hardness tester is a combination of Shore Hardness tester and Shao Hardness tester support. Shore Hardness tester can also be used with other supports.

Product Details

Hardness tester product introduction:

Product name: Shore Hardness tester

Shore hardness tester tester is equipped with type A or D Shore hardness tester and type C microporous material hardness tester.

The upper end of the frame is equipped with a constant load weight to accurately measure the hardness of rubber or microporous materials.

Basic parameters of hardness tester:

Dimensions: 200x150x275mm

Weight: 1Kg

Weight: 7.9Kg

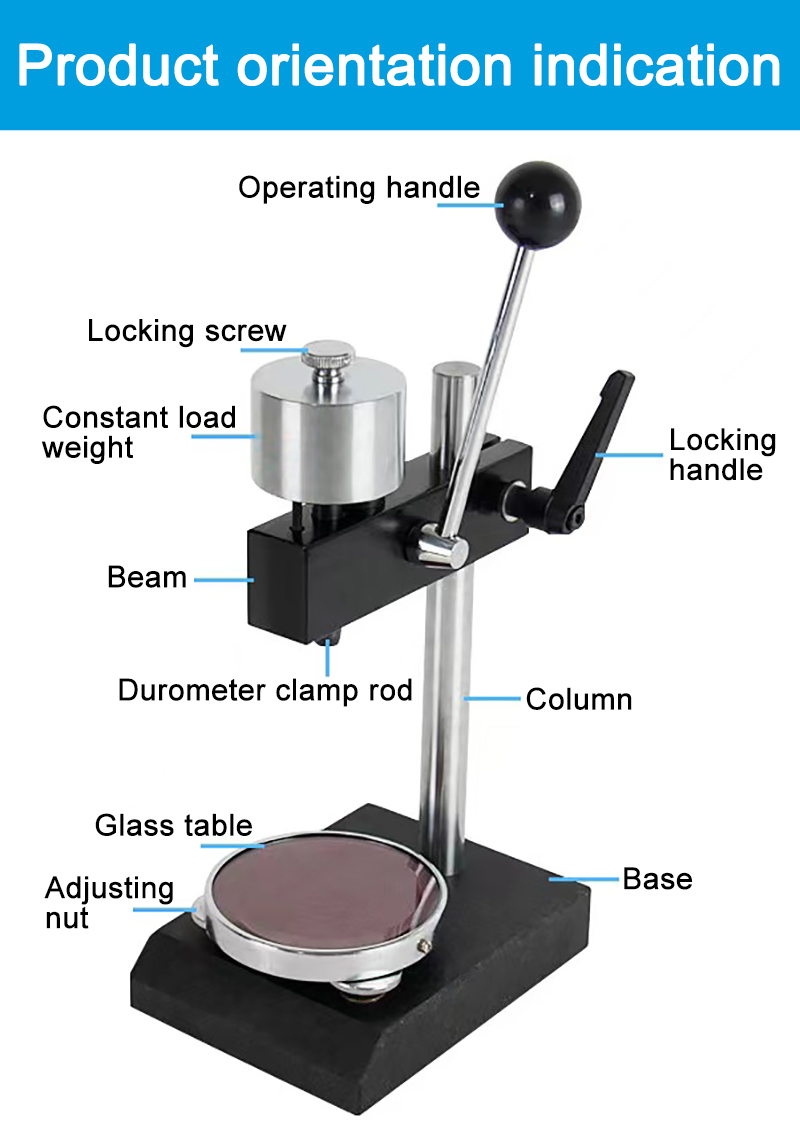

Handle: The amount of force applied to the measured object when measuring the object.

Star handle: Adjust the height of the arm.

The use of hardness tester:

Place the sample on a firm surface, hold the hardness tester, press the needle at least 12mm away from the edge of the sample with a steady pressure foot, press the needle vertically into the sample, until the pressure foot and the sample completely contact the reading within 1S, measure the hardness value for 5 times at different positions at least 6mm apart from the measuring points, and take the average value (microporous material measuring points at least 15mm apart). In order to stabilize the testing conditions and improve the testing accuracy, the hardness tester should be installed in the matching production of the same type of testing rack.

Product overview of hardness tester:

The test principle is more scientific, the structure is more compact and reasonable, and the stability and accuracy of the test are further improved. And the use of high hardness metal platform instead of the traditional glass platform, effectively avoid the glass platform fragile shortcomings, especially in the D hardness test, users no longer need to be equipped with special hardness blocks, making the test more economical and convenient.

Note on the use of hardness tester:

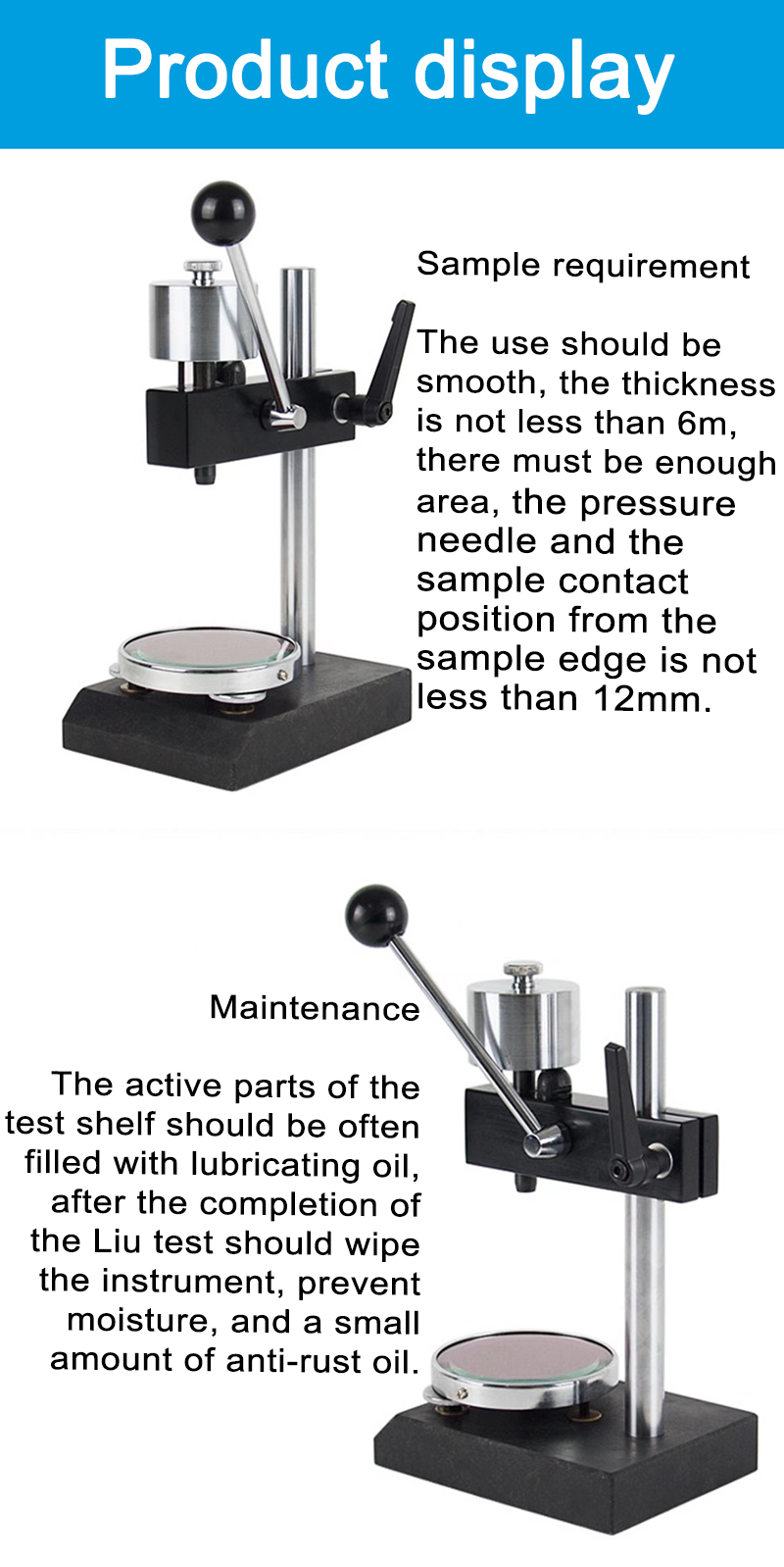

1.sample requirements:

(1) The sample is flat, the thickness is not less than 6mm, and there is enough area. The contact position between the pressure needle and the sample is not less than 12mm from the edge of the sample.

2. Installation and debugging:

(1) The test rack should be placed on a stable and smooth workbench, and then the height of the transverse arm should be adjusted. During operation, release the star support hand with the right hand, and lift the cross arm with the left hand so that the bottom of the durometer mounting rod is about 110 away from the table surface of the circular platform, and tighten the star handle (the durometer mounting rod should be aligned with the circular platform).

(2) the dust-proof cap on the top of the durometer is unscrewed, and then the durometer into the installation rod of the test frame, and tighten (tighten not force, otherwise it will damage the durometer), tighten such as the surface of the durometer is not aligned with the operator, you can loosen the bearing adjustment knob on the top of the weight, and then rotate the durometer to the ideal Angle after tightening the bearing adjustment knob.

(3) Loosen the star handle on the cross arm, and adjust the height of the cross arm again with the left hand until the distance between the bottom surface of the hardness tester and the test frame is round

When the platform surface is about 10mm, tighten the handle and press down the handle of the test frame, so that the press foot is in complete contact with the circular surface, and slowly turn the two fine-adjusting handwheels under the circular surface until the hardness tester shows 100 degrees (1 degree soil). At this time, the installation and debugging of the test frame and hardness tester are completed.

Product maintenance of hardness tester support:

The active parts of the durometer test frame should be often filled with lubricating oil. After the test, the instrument should be wiped clean to prevent moisture and coated with a small amount of anti-rust oil.

Warm tip: Due to the hardness tester upgrade, hardness tester picture for reference only, details email consultation! More quality products welcome your consultation!

Dongguan Runzhi Electronics Co., LTD. - Testing Instrument Division, founded in 2011, is a high-tech enterprise with many years of professional electronic technology and instrument research and development professionals to set up a set of professional laboratory testing equipment, research, development, manufacturing.

Dongguan Runzhi Electronics Co., Ltd. mainly engaged in special instruments and equipment are: Laboratory environment test instrument, element detection instrument, floor residual pitting meter, lock size tester, straight Angle detector, microcomputer push tension meter, static bending strength testing machine, high-precision image projector, caster testing machine, falling ball tester, falling sand meter, 90 degree peeling strength testing machine, scratch resistance tester, wear resistance tester, gloss meter, whiteness meter, Energy meter, hydrometer, infrared thermometer, viscometer, thickness meter, depth meter, analytical balance, caliper, gauge and other instruments and equipment.

Dongguan Runzhi Electronics Co., Ltd. operating products with strong targeting, a wide variety of functions, excellent quality, adequate inventory, after-sales support and other advantages, welcome new and old customers all over the country to call to mail consultation:

Dongguan Runzhi Electronics Co., Ltd.

Contact Person: Mr. Zheng

Department: Business Department

Post: Sales Manager

Telephone: +86 13712847488

Landline: +86 13717173764

Company Address: Room 101, 33 Zhenma Road, Dalingshan Town, Dongguan City, Guangdong Province,China

Factory Address: Room 101, No. 33 Zhenma Road, Dalingshan Town, Dongguan City, Guangdong Province,China

Website: runzhi.us764.com

Previous: hygrometer

Next: Kinematic Viscometer