Products

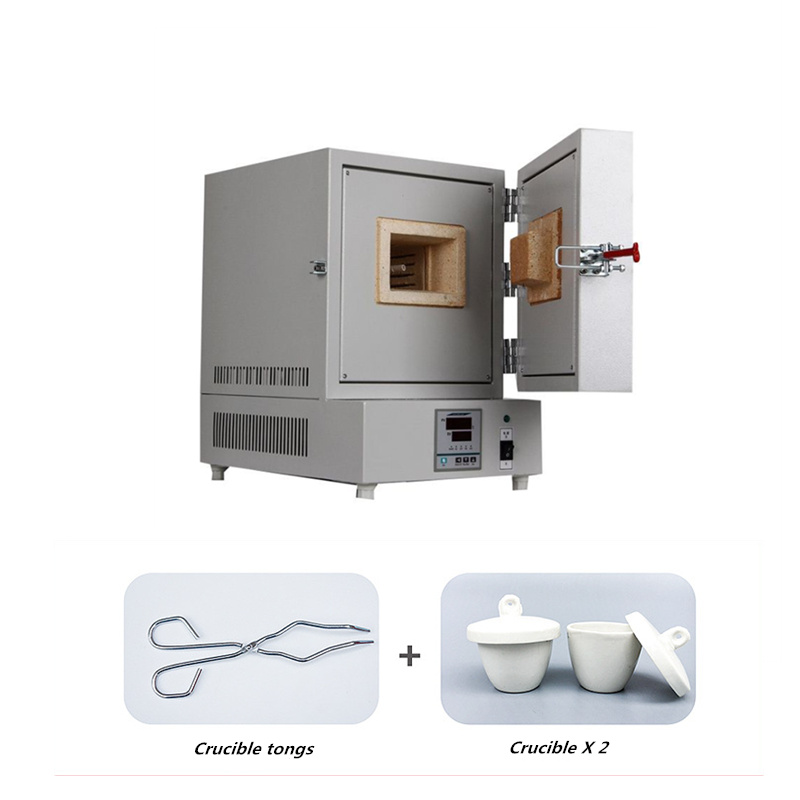

Muffle furnace

Five Advantages Of Products

- It adopts a double-layer shell structure and is equipped with an air cooling system, so that the temperature of the shell surface is less than 60 degrees.

- The furnace material adopts high-purity alumina polycrystalline fiber, which is durable in heat preservation and 50% energy saving.

- The heating element adopts high-quality silicon molybdenum rod, the highest heating temperature can reach 1700℃; The furnace door is left-opening, with safe operations such as opening the door to cut off power, over-temperature alarm, and leakage protection.

- The intelligent temperature control system has PID adjustment and self-tuning functions, and can program 30 sections of temperature rising and falling programs; the temperature control accuracy is ±1℃.

- The furnace is equipped with a 485 conversion interface, which can be connected to a computer. Through a dedicated computer control system to complete remote control, real-time tracking, historical records, output reports and other functions with a single or multiple electric furnaces.

Product Details

"Can be customized according to customer requirements"

Company Profile:

Welcome to "Dongguan Runzhi Electronics Co., Ltd.", the company was established in 2011, professionally equipped with a complete set of testing equipment, research, development, and professional manufacturing of high-tech equipment in the PVC, WPC, and SPC plastic floor industry laboratory. The company’s main floor special instruments and equipment are: constant temperature and humidity box, aging tester, residual concavity meter, size tester, push-pull force meter, scratch resistance tester, wear tester, energy meter, hydrometer, infrared measurement Thermometer, gloss meter, color measuring instrument, viscometer, thickness meter, depth meter, density meter, feeler gauge and other instruments and various measuring tools. The company specializes in testing equipment products with reliable quality, affordable prices, sufficient warehouses, etc., with strong strength, high-quality after-sales services and other characteristics to win the trust of customers, and has become a leading PVC flooring company "Taiwan Meizhe International Enterprise Co., Ltd. ", "Jiangsu Bell Decoration Materials Co., Ltd.", "Zhejiang Hailide New Materials Co., Ltd." and other designated supply units!

The following is an introduction to the incinerator:

The incinerator is also called resistance furnace (box-type resistance furnace), muffle furnace, electric furnace, Maofu furnace, and muffle furnace. The incinerator is a universal heating equipment. According to the appearance and shape, it can be divided into box furnace, tube furnace and crucible furnace. It can be used for element analysis and determination and small rigid parts quenching, annealing, and tempering. Heating metal, ceramic sintering, High temperature heating such as dissolution analysis, plastic ash detection, baking in the denture processing industry, pre-sintering of zirconia discs, etc. It is suitable for scientific research in universities, research institutes, laboratories of industrial and mining enterprises, etc.

"Can be customized according to customer requirements"

Precautions for use of incinerator:

When the incinerator is used for the first time or after a long period of inactivity, it must be oven dried: open the oven door at 20~200℃ for 2-3h, and close the door at 200~600℃ for 2-3h. The thermostat should avoid vibration, and the location should not be too close to the electric furnace to prevent overheating and preventing the electronic components from working properly. When moving the thermostat, set the power switch to "off". Before use, adjust the thermostat to the required working temperature, turn on the start code to energize the incinerator. At this time, the ammeter has a reading, and the temperature measured by the temperature control meter gradually rises, indicating that the incinerator and thermostat are working normally.

The working environment requires that the relative humidity does not exceed 85% and the ambient temperature is 0-40℃. There is no conductive dust, explosive gas or corrosive gas. It is forbidden to directly pour various liquids and molten metals into the furnace, and always keep the furnace clean.

When in use, the furnace temperature shall not exceed the maximum furnace temperature, nor shall it work for a long time at the rated temperature. During the experiment, the user is not allowed to leave and pay attention to temperature changes at any time. If an abnormal situation is found, the power should be cut off immediately and repaired by professional maintenance personnel. .When using, the furnace door should be lightly closed and opened to prevent damage to the parts. Crucible tongs should be handled gently when taking samples to ensure safety and avoid damage to the furnace.

Do not open the furnace door after the temperature exceeds 600 degrees. Open the furnace door after the temperature in the furnace cools naturally. After the experiment is completed, the sample is withdrawn from heating and the power is turned off. When the sample is placed in the furnace, the furnace door should be opened slightly. After the sample has cooled down, the sample should be carefully clamped to prevent burns. The heated crucible should be transferred to a desiccator for cooling, and placed on a buffer refractory material to prevent moisture absorption, explosion and cracking, and then weighed.

When handling the muffle furnace, pay attention to avoid serious resonance, and place it away from flammable, explosive, and water. It is strictly forbidden to lift the furnace door to avoid damage to the furnace door.

The following are the precautions for maintenance of the incinerator:

Regularly check whether the wiring of the electric furnace and the controller is in good condition, whether the pointer of the indicator is stuck or stagnated when moving, and use a potentiometer to verify the fatigue and balance of the meter due to magnetic steel, demagnetization, wire expansion, and shrapnel Increased error caused by destruction.

Do not pull out the thermocouple suddenly at high temperature to prevent the jacket from bursting.

Keep the furnace chamber clean and remove oxides in the furnace in time

"Can be customized according to customer requirements"

Dongguan Runzhi Electronics Co., Ltd.

Contact Person: Mr. Zheng

Department: Business Department

Post: Sales Manager

Telephone: +86 13712847488

Landline: +86 13717173764

Company Address: Room 101, 33 Zhenma Road, Dalingshan Town, Dongguan City, Guangdong Province,China

Factory Address: Room 101, No. 33 Zhenma Road, Dalingshan Town, Dongguan City, Guangdong Province,China

Website: runzhi.us764.com

Previous: Aging tester

Next: gloss meter